by Heikki Hassi & Panu Tikka

When an engineer, often together with scientists, is working with concepts; analyzing and improving them, aiming at choosing the optimal one and confirming its feasibility, she or he is performing conceptual engineering1).

- Concept: An idea of something formed by mentally combining all its characteristics or particulars; a construct 2).

- Engineering: The art or science of making practical application of the knowledge of pure sciences, as physics or chemistry, as in the construction of engines, bridges, buildings, mines, ships, and chemical plant 2).

For industrial investors and project managers, conceptual engineering is the first of the three main stages of engineering. It precedes basic engineering and detail engineering. The more novelty is involved, the more emphasis is given to the conceptual kind.

When talking about the “Green Shift” – a rising megatrend influencing many process industries, but yet to be well defined, the term “conceptual engineering” may refer to one of the two different, yet often causally related activities:

- Conceptual process engineering, for the purpose of transforming a hypothetical process, e.g., an idea of a novel chemical biomass fractionation process, into an industrially realizable mill process.

- A knowledge-based, i.e., “engineer-like” examination of a traditional philosophical or intellectual concept, e.g., the concept of ecological sustainability, for the purpose of improving or updating it 3).

Illustrative of the relationship of these two is that the strong and accelerating evolvement of the concept of ecological sustainability generates equally strong need for novel and improved industrial processes for and within various industries and value chains. The driver of the growing demand for conceptual process engineering couldn’t be more fundamental.

This is especially true in the field of biomass conversion processes, which is diversifying as the demand for novel biomass-based materials, end-use applications and products is growing strongly.

Mankind is moving towards sustainable circular bioeconomy, step by step. It’s a long journey, which requires travelling beyond the beaten tracks and opening many novel routes and paths. Scouting the terrain ahead, drawing and using maps for proper orienting – and, indeed, taking the steps – are preconditions for steadily advancing towards the goal and not getting lost.

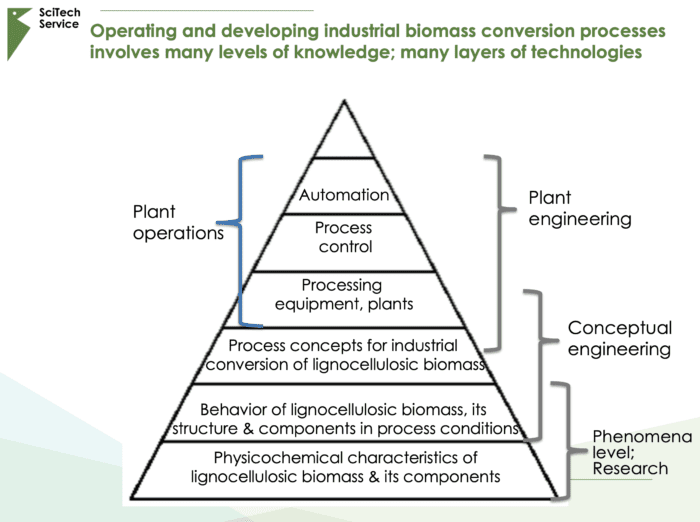

Conceptual process engineering aiming at chemical conversion of wood or other lignocellulosic biomass must be founded of strong knowledge of the structure and the composition of the biomass feedstock and its constituents, and their behavior in relevant process conditions and, equipment, as illustrated in Figure 1.

Keeping this in mind, the necessity of conceptual process engineering is self-evident, e.g., when developing a novel process for the production of new kind of biomass-based products, (like 2nd generation bio-ethanol or advanced bio-diesel made of Nordic wood species).

Equally clear cases are, e.g., up-scaling of a novel straw-pulping process or the several on-going demo-scale investment projects aiming at industrial break-through of novel cellulosic textile fibre manufacturing processes in Finland and Sweden. Due to the current diversification of the global bio-products industry, many more equally clear examples could be given.

In cases like this, novel fundamental knowledge of the behavior of the selected wood species – or a non-wood feed stock – in relevant process condition is to be generated through well designed experimental research. Over the years, very long list of different wood species and agricultural residues have been experimentally processed at SciTech-Service’s fully owned pulping laboratory and pilot plant (Experimentis Oy) in Rauma, Finland.

Conceptual process engineering is needed also when adjusting an existing industrial process for new kind of feedstock (e.g., certain larch species instead of pine or spruce) or when changing from paper pulp production to chemical grade cellulose production, to give some timely examples.

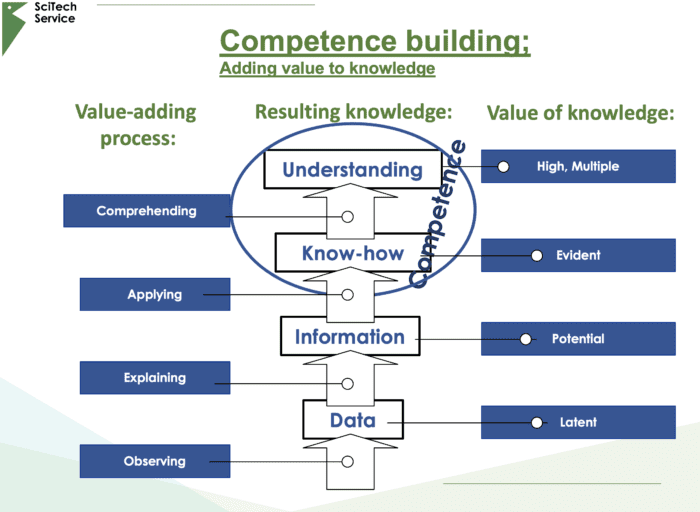

Conceptual process engineering is a value-adding process, which combines novel information generated through research with earlier knowledge and available know-how, and then transforms all this into a concept report, written and edited to serve the needs of the customers – usually high-level experts in the forest industry or other bio-based industries, in an engineering company or at an equipment manufacturer.

Along this process, value of the information rises as illustrated in Figure 2.

Typical elements of a concept report are a block diagram of the process; material and energy balances; preliminary equipment dimensioning. These elements can be combined to a flow diagram, which explains the parts and the operations of the process. Supported by experimental results, their interpretation, and verbal description of the process, such flow diagram is the core of concept report. It provides solid basis for entering the next step towards an industrially realizable mill process, namely basic engineering.

Conceptual process engineering builds a bridge from science and researchers to plant engineers, investment project teams and production personnel. After having done this bridge-building in SciTech-Service for some 30 years, we still see it as a very stimulating field. We are geared to serve our customers in various industries, emerging enterprises and innovative R&D projects.

Notes and references:

- Also called “conceptual design”. I prefer “engineering”, which (to me) represents also the functionality, or capability of operating, while “design” represents form and structure. A matter of taste, really.

- https://www.dictionary.com

- https://philpapers.org/browse/conceptual-engineering