Kraft pulp mill process has become the only dominating cooking process for making chemical pulp. In the 1980’s started an active period where a lot of old conventional cooking capacity were replaced by new mills; In the same context the unit size of the cooking plants and production capacity grew substantially, to more than million tons per digester today.

The vigorous research and technical development of several competing process solutions uncovered surprisingly big variability how different kraft cooking processes delivered pulp quality, especially paper technical strength properties. Scitech-Service Oy Ltd and its laboratory were in key research position together with some Pulp&Paper industry and R&D institutes.

In brief: The old paradigm of milder chemical conditions benefit for pulp quality did not seem to hold true anymore. Some process variants produced clearly stronger pulp than others, although the latter ones were modified for milder conditions and resulted in higher pulp viscosity (less chemical damage and molecular level). After eliminating all the possible error sources and thanks to the so called basket-cooking mill study technique, the following fact emerged:

Cooking and fiberline mechanical process conditions caused physical damages and deformations in the pulp fiber walls.

The wall laminar structures partly dissolve and the alkaline liquid inside the walls loosen their structure making fibers vulnerable to undergo damage by mechanical forces. Thus, the physical conditions in the process: compaction, shear forces, friction, throttling valves, mixers, all compromise pulp strength – the more the fiber wall has been de-laminated and loosed internal structure.

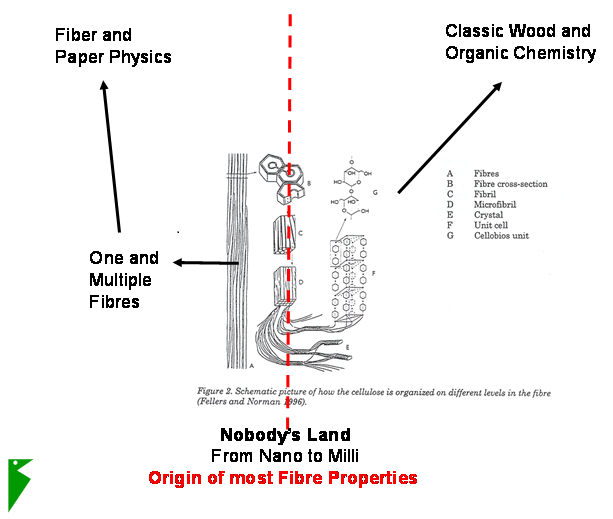

It is evident that the structure changes in the scale from micrometers to millimeters (microfibrilles to fiber length) play important role and can explain up to 40% losses of pulp strength. Besides the well-known world of molecules and macromolecules there is another influential realm of the fiber structure sub-millimeter features. Today the process performance principles have found new applications in paper physics and paper & carton board trouble-shooting and end-product quality development.

References:

- Tikka, P.O., MacLeod, J.M., Kovasin, K.K., Chemical and Physical Performance of Kraft Cooking: The Impact of Process Alternatives. TAPPI Journal 74(1991):1, p 137.

- Tikka, P.O., Sundquist, J., Softwood fiber damage – A newly discovered enigma in modern kraft fiberlines. TAPPI 2001 Pulping conference, Nov. 4-7, 2001, Seattle, WA, USA.

- Tikka, P.O., Pulp Quality – Not Only Chemistry. 3rd Int.natl. Colloq. on Eucalyptus Pulps, Feb. 4-7, 2007 Belo Horizonte, Brazil