The textile industry, most visibly the leading fashion brands and entrepreneurs, are busy with efforts to translate the imperative of textile recycling into profitable business. The search for sustainable future is the mega-driver of this transformation.

The opportunity is considerable; every year the industry converts some 100 million metric tons of various textile fibres into yarns, fabrics – and to those branded products of high added-value. However, only some 1% of textiles are currently recycled and reused within the industry. This sizeable, underutilized raw-material resource is now getting proper attention. And much more than that is at stake – neglected textile recycling easily deteriorates companies’ reputation and brand value, unless corrected by swift action.

To many in the modern textile industry it may come as news that used textiles – or rags – have a very long history of being in high demand for industrial re-use. However, the historical recycler was not the textile industry, but the early paper industry. Mark Kurlansky unveils this interesting story in his brilliant book, “Paper – paging Through History” 1), the main source of information for this brief commentary on the topic.

In 794, the grand Abbasid caliphate had a paper mill built in Baghdad, based on the know-how developed in China. It was a response to the capital’s need of paper, as papyrus and parchment couldn’t meet the growing needs of the communication, record keeping, media and arts. Baghdad was a perfect location for a paper mill as its population was large enough to produce rags to be used as raw material for the paper mills. The location at the river Tigris helped further.

Somewhat puzzling, it took several centuries before paper mills and the industrial use of rags entered Europe. However, in the twelfth century, there were already rag paper mills in Catalonia and Basque country, and through the fourteenth and fifteenth century, local paper mills flourished in Spain and Italy, and the industry also spread to the north of the Alps.

The demand of paper – and rags – kept on growing, driven by the bursting of intellectual life, which, in e.g, led to the founding of universities. To imagine the role of paper in those times, just consider the importance of digital information technology today. Kurlansky refers to the Spanish author Francisco de Quevo (1580 – 1645), who wrote:

Those that were rags yesterday,

and thrown away by the cook,

are today documents that govern the worlds

and threaten three others.

Linen and cotton rags were preferred for better grades of paper; hemp from both cloth and ropes was also used for lower grades.

The greatest limitation on paper production was getting enough rags; local administrations of Fabriano, Florence, Venice, Signora and Genoa forbid the exportation of rags, and many other European governments followed.

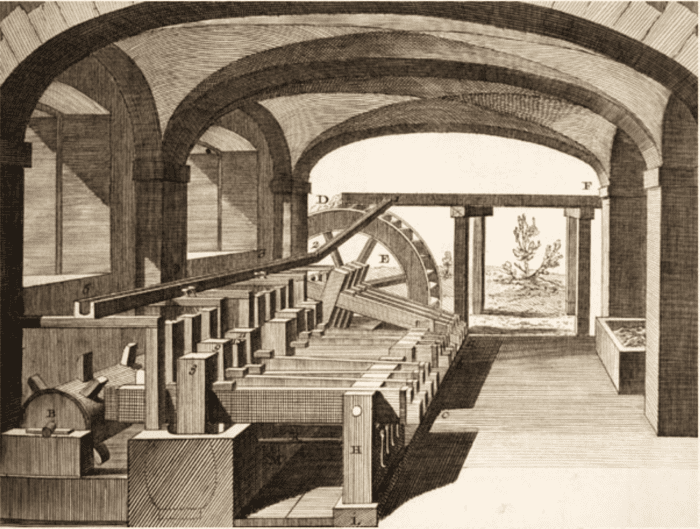

Figure 1. Stamper-beater at a rag paper mill, for pre-treatment of rags. 2)

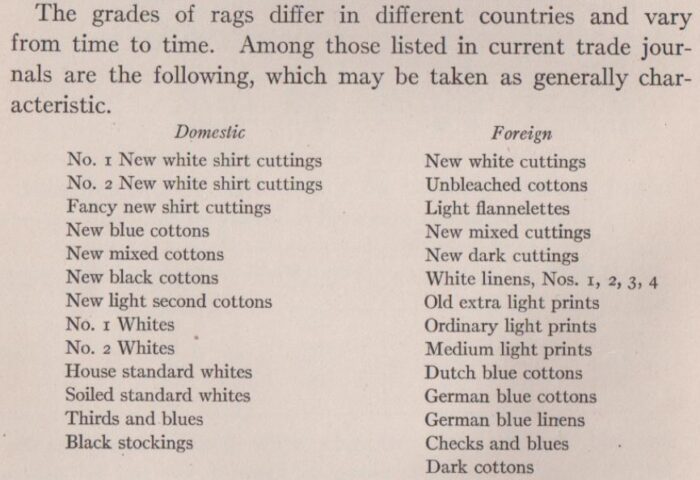

The use of rags for paper making continued even after industrial processes for the manufacture of paper pulp from wood and other types of lignocellulosic biomass were well established. In Edwin Sutermeister’s book “Chemistry of Pulp and Paper Making” 3), published in 1920, the topic of collecting rags still gets fair attention. Reflecting the advancement of paper making and printing technologies, also rags were now sorted accordingly. The textile and fashion industry had advanced as well.

Figure 2. Table from Sutermeister 3)

The non-existence of synthetic fibre like polyester at that time made sorting reasonably easy – their introduction to the textile industry was still some two decades ahead. Cotton and linen had taken global dominance and wool had lost it.

Today, the situation is different!

Most textiles are composed of several different fibres; e.g., blends of cotton and polyester are very common. About two thirds of the 100 million tons of annual textile fibre manufacture is polyester and other synthetics. About one quarter of it is cotton, i.e. natural cellulose fibre, and another 6% is Man-made Cellulosic Fibres (MMCFs), mostly viscose fibre, and, to a lesser but rapidly growing extent lyocell fibre.

All those cellulosic textile fibres are composed of high-purity cellulose, enabling their relatively easy re-use as feed stock for MMCF manufacture in processed, where the cellulose is dissolved. Cellulose-rich recycled textiles (the term “rags” has been left for history books) can be cleaned of small amounts of polyester fibres in a chemical pre-treatment. For the re-use of all different fibre types, including the synthetic ones, novel concepts and technologies need to be developed.

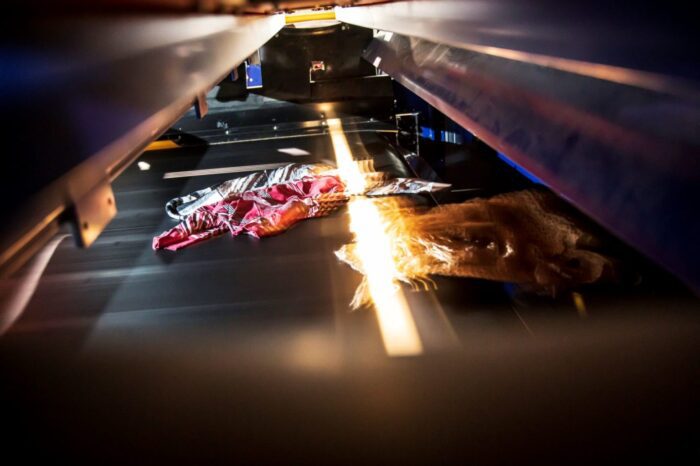

As the term “rags” was left in history, so were the practices of collecting and sorting of used textiles for industrial re-use. An efficient, modern version of textile recycling is still under development. Getting from today’s c. 1% recycling rate in textiles to close to the normal practice in paper industry is still far away; there, more recycled paper fibres are used than virgin fibre pulps, globally.

Indeed, the textile industry and the entrepreneurs are busy for a very good reason; closing the textile value chain is both an imperative and an opportunity, in large scale.

Figure 3. Modern textile sorting facility4)

References:

1) Mark Kurlansky: Paper – Paging Through History; W.W.Norton & Company, Inc. 2016

2) Encyclopédie, ou Dictionnaire raisonné des sciences, des arts et des métiers, vol. 5, Diderot & d’Alembert. Paris, Briasson [etc.] 1751–65

3) Edwin Sutermeister: Chemistry of Pulp and Paper Making; John Wiley & Sons, Inc. 1920

4) https://www.recycling-magazine.com/2021/02/18/worlds-first-fully-automated-textile-sorting-plant-in-malmo/